In disaster relief and military operations, time is the most critical resource. When infrastructure is compromised or non-existent, the speed at which a command center, field hospital, or temporary shelter can be established often determines the success of the mission. Traditional rigid-frame tents and container-based solutions, while durable, often suffer from significant logistical bottlenecks regarding weight, transport volume, and setup complexity.

Inflatable medical and military tents utilizing air-beam technology have emerged as the superior solution for rapid deployment scenarios. By replacing heavy metal poles with pneumatic structures, these shelters offer a high strength-to-weight ratio and unmatched portability. This guide analyzes the strategic advantages of inflatable structures for institutional buyers, NGOs, and defense procurement officers, focusing on technical specifications, operational benefits, and procurement considerations.

The Engineering Behind Air-Beam Technology

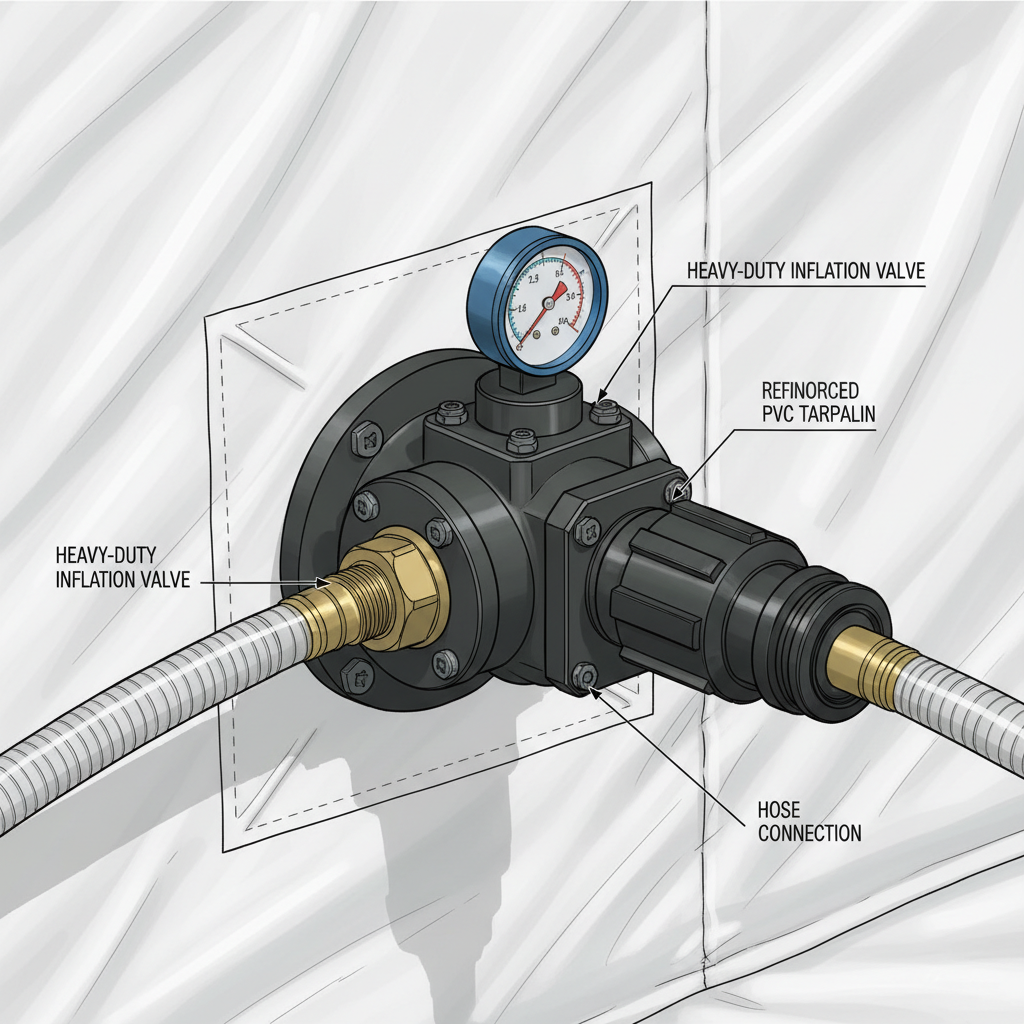

Unlike traditional tents that rely on aluminum or steel skeletons, rapid deployment inflatable tents use air-beams (also known as pneumatic tubes) as the primary structural element. These beams are typically constructed from high-strength PVC tarpaulin or TPU (Thermoplastic Polyurethane) materials, radio-frequency (RF) welded to create airtight seals.

Sealed Air vs. Constant Air

For medical and military applications, sealed air (airtight) systems are the industry standard. Once inflated, the valves are closed, and the structure maintains pressure for days or weeks without requiring a continuous power supply. This is distinct from “constant air” inflatables (like bounce houses) that collapse immediately if the blower stops.

- Silence: Sealed units do not require a running generator or blower, creating a quiet environment essential for medical triage or tactical communication.

- Independence: They remain standing during power outages, a critical feature in disaster zones.

- Thermal Insulation: The air gap within the beams provides a degree of natural insulation, which can be enhanced with additional liners.

Comparative Analysis: Inflatable vs. Rigid Frame Shelters

When evaluating shelter systems for procurement, it is essential to compare the logistical footprint and operational readiness of inflatable units against traditional rigid-frame options.

| Característica | Inflatable Air-Beam Tent | Rigid Metal Frame Tent |

|---|---|---|

| Setup Time | 5–15 minutes (with electric pump) | 45–90 minutes (manual assembly) |

| Manpower | 2–4 personnel | 4–8 personnel |

| Pack Volume | Compact (fits on standard pallets) | High (long poles require specialized transport) |

| Peso | Lightweight (no heavy metal) | Heavy |

| Terrain Adaptability | High (flexible base) | Moderate (requires level ground) |

Critical Use Cases in Field Operations

1. Mobile Field Hospitals and Triage Units

Inflatable medical tents are designed with hygiene and modularity in mind. Manufacturers can incorporate features such as detachable PVC floors (to allow for easy cleaning and decontamination), negative pressure capabilities for isolation wards, and bright white interiors to maximize lighting efficiency. The rapid setup allows medical teams to begin treating patients within minutes of arrival.

2. Military Command Posts (TOC)

Tactical Operations Centers require protection from the elements and secure environments for sensitive electronics. Inflatable military tents often feature blackout materials to prevent light leakage at night and can be equipped with cable sleeves for organized IT infrastructure. Their low weight makes them air-droppable or easily transportable by light tactical vehicles.

3. Decontamination Showers

Specialized inflatable structures are used for HazMat response. These units are typically compartmentalized into undressing, washing, and dressing zones. The inflatable framework supports the plumbing and containment basins necessary to capture contaminated runoff.

Especificaciones del material y durabilidad

For B2B buyers, understanding the material specifications is crucial to ensuring the longevity of the investment. Cheap recreational materials will not withstand the rigors of field deployment.

- Primary Material: Heavy-duty PVC Tarpaulin (typically 0.6mm to 0.9mm thickness) is the standard for the air beams and outer shell. It is waterproof, UV resistant, and abrasion-resistant.

- Flame Retardancy: Tents intended for human occupancy must meet international flame retardant standards (e.g., B1, M2, or NFPA 701 equivalent). Always request material data sheets (MDS) during procurement.

- Temperature Resistance: High-quality commercial inflatables are engineered to function in extreme temperature ranges, typically from -30°C to +70°C, ensuring reliability in both desert and arctic conditions.

- Valves: Pressure relief valves are a critical safety feature. They automatically release excess air if the internal pressure rises too high due to thermal expansion (e.g., hot sun), preventing the beams from bursting.

Customization Options for Institutional Buyers

One of the primary benefits of working directly with a manufacturer is the ability to customize the structure to specific operational requirements. Off-the-shelf solutions may not fit every scenario.

HVAC and Environmental Control

Tents can be manufactured with dedicated duct sleeves to connect external HVAC units or heaters. This is mandatory for medical tents where patient temperature regulation is vital, or for military units operating in extreme climates. Removable insulation liners can also be added to improve thermal efficiency.

Modularity and Connectivity

Many systems are designed to be modular. Tents can be connected end-to-end or via 4-way docking hubs to create large, multi-room complexes. This allows a field hospital to expand its capacity seamlessly without needing entirely new infrastructure.

Branding and Identification

For NGOs and relief agencies, visibility is key. Tents can be produced in specific colors (e.g., UN Blue, Red Cross White, Military Olive Drab/Sand) with logos printed directly onto the material or attached via Velcro banners for interchangeable identification.

Buying Guide: Key Procurement Considerations

When sourcing inflatable medical or military tents, consider the following factors to ensure the product meets your logistical needs.

1. Lead Times and MOQ

While some standard models may be in stock, customized orders generally require production lead times ranging from 2 to 6 weeks depending on quantity. Minimum Order Quantities (MOQ) for industrial inflatables are often low (sometimes as low as 1 unit), allowing for trial orders before fleet deployment.

2. Accessory Packages

Ensure the quote includes all necessary deployment gear:

- Electric Pumps: High-volume pumps for rapid inflation.

- Manual Pumps: Backup options in case of power failure.

- Anchoring Systems: Heavy-duty stakes, sandbags, and guy ropes are essential for wind resistance.

- Repair Kits: Patches and adhesive for field repairs.

3. Quality Assurance (QA)

Ask about the manufacturer’s testing process. Reputable factories inflate every unit for at least 24–48 hours prior to shipping to check for air leaks. Requesting photos or video of your specific unit during this test phase is a standard practice in international trade.

Preguntas más frecuentes (FAQ)

Q: How do inflatable tents perform in high winds?

When properly anchored with stakes and guy lines, high-quality inflatable tents can withstand wind speeds of 60–80 km/h (Force 8). The flexibility of the air beams allows them to bend slightly under gusts rather than snapping like rigid poles.

Q: Can these tents be repaired in the field?

Yes. Small punctures can be repaired in minutes using a standard repair kit (PVC patch and glue) or heat welding tools, similar to repairing a tire or an inflatable boat.

Q: What is the lifespan of a PVC inflatable tent?

With proper care and storage, heavy-duty PVC tents can last 5–10 years. UV exposure is the primary factor in degradation, so using UV-treated materials is essential.

Q: Do I need a continuous power supply?

No. Sealed air tents only require power during the initial inflation (or occasional top-ups). They are designed to hold pressure for extended periods.

Conclusion

Inflatable medical and military tents represent a shift towards agility and efficiency in emergency response. By significantly reducing weight and setup time without compromising on durability or protection, these structures allow organizations to deploy faster and operate more effectively in challenging environments. For procurement officers, selecting the right partner involves evaluating material quality, customization capabilities, and long-term support.

Ready to upgrade your rapid deployment capabilities? Contact our team today to discuss specifications, request a quote, or arrange a sample for your organization.